[:bg] Implementation of Total Productive Maintenance (TPM) в пилотна линия В голямо предприятие от металообработващата индустрия съвместно с мениджмънта работихме за внедряването на модула „Тотална продуктивна поддръжка“ (TPM). In this article we will show you some details of the work in one of the lines, selected as "pilot". Първоначално ръководството ни...

5S in the production of plastic products

[:bg]5S in the production of plastic products. Преди да се внедри 5 S in the workshop there was no systematic arrangement and visual management. The layout was not built well and despite the presence of some markings, they were not observed. The workplaces were missing the markings, to denote the distribution of space. Навсякъде имаше хаос – малките инструменти и нужните...

Lean methodology in the textile industry

Резултати от лийн методологията в текстилния бранш Лийн методологията в текстилния бранш. There is an opinion, that good results through lean methodology are achieved mainly in machine building and in the automotive industry, but is it so ? We are participating in a project on the implementation of lean tools in the textile industry. С нястоящия пост споделяме някои...

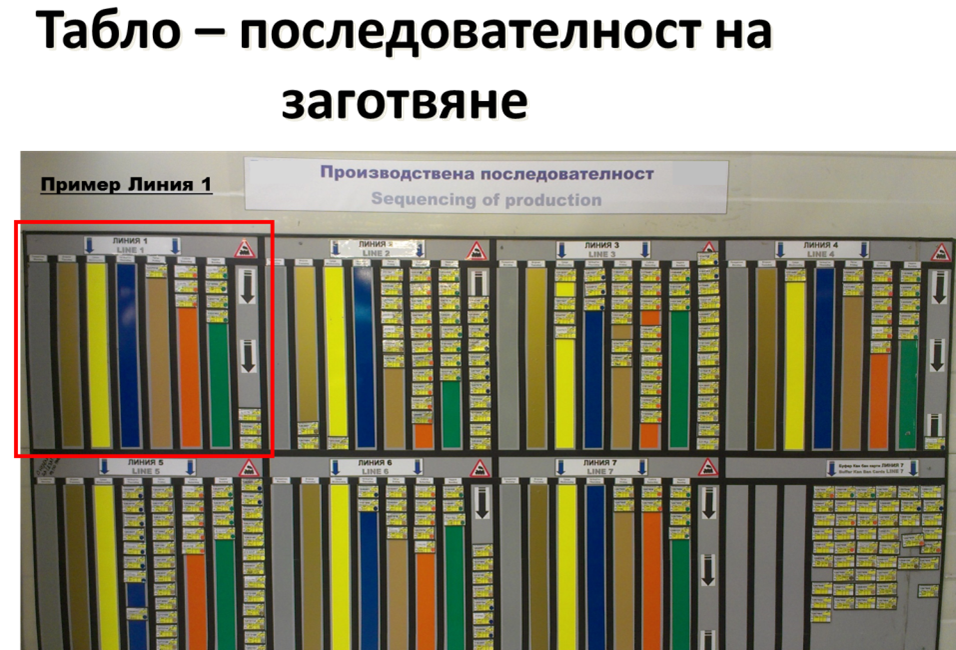

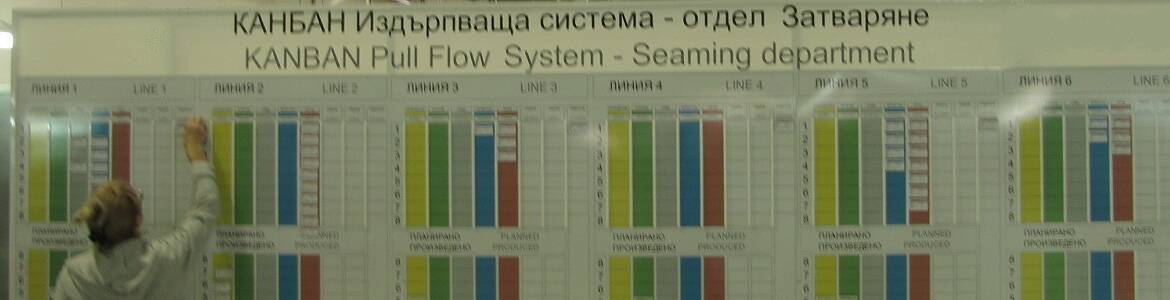

Kan Ban in the textile industry

The example, which will be considered refers to production, which sews headrest covers for cars. The volumes, with which to work are large - around 20 thousands a day of 500 operator. Before the introduction of pull system, the chaos in the production lines created many problems such as: натрупване на огромно количество материали в...

Kan-ban

[:bg] makes planning easier, improves communication between the production department and the logistics department, намалява суровия материал в производствените участъци намалява междуоперационните запаси съкръщава времето без добавена стойност лесно се разбира от всички нива в организацията. More about the project - тук.[:in] makes planning easier, improves communication between the production department and the logistics department, намалява суровия материал...

Lean creates flow…

[:bg]In many companies, the production flow is restricted and blocked. Often the production structure (layout) it is not well thought out and creates problems with moving the series. The operations are not balanced and accumulations occur before the bottlenecks. Lack of good planning practices, requires frequent changes, които много трудно се координират с всички звена...

Тотална продуктивна поддържка

[:bg]"Медицинската наука" за производствения организъм. TRM is aimed at: creating a company culture that maximizes the efficiency of the production system; practical organization of production to prevent losses before they occur, throughout the life cycle of the production system with a view to achieving zero accidents, нула...

Orderliness and cleanliness in production?

[:bg]5S is a tool, through which a perfect organization of the workplace is achieved. 5S is an important tool for industrial culture change. 5S is "silent informant" about the company's attitude to quality and everything else. Example of a 5S project - here. More about 5S - here. [:in]5S is a tool through which perfect...