Total productive support (Total Productive maintenance) TRM is a system, created and developed in Japan over several decades. With an initial focus on manufacturing and machinery, it evolved into a program, covering almost all activities in the organization. TRM is aimed at: създаване на фирмена култура която да максимизира ефективността на...

JIT – just-in-time production

Just in time production или производство „Точно навреме“ JIT - "Just in time" production in the Bulgarian industry sounds almost mystical. We are used to associate them with logistics activity, omitting the fact, that Just in Time is one of the two pillars of Toyota's production system. Just in time means producing just that, което...

5 S - Five steps to organizing the workplace

5 S – Пет стъпки към организиране на работното място Всички искаме работните места да са чисти и подредени, so that operators don't waste time searching for adjustment keys, for technicians to find the parts and tools they need in the shortest possible time, the workshop to look neat, etc. Ежедневието обаче ни сблъсква...

Lean thinking

Lean is a management approach, which directs and limits the expenditure of production resources solely and only in achieving goals, which create added value for the end customer. За да може Lean да бъде внедрен като подход в едно производство и то да стане от Световна Класа трябва всички да променят начина...

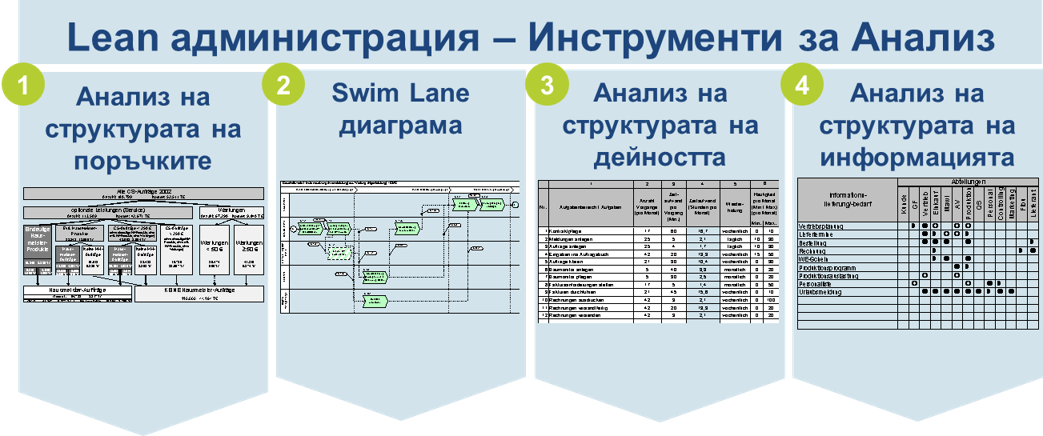

Lean in Administration

Лийн в Администрацията или „Ефективни бизнес процеси, представени чрез забавна симулация“ Защо Лийн в Администрацията? The main focus for improvements is only in production. Административни процеси ПРЕДИ Останалите процеси не се анализират и липсва връзка между тях. We don't know how to look for losses/wastes in administrative processes. Искате да знаете какви са методите...

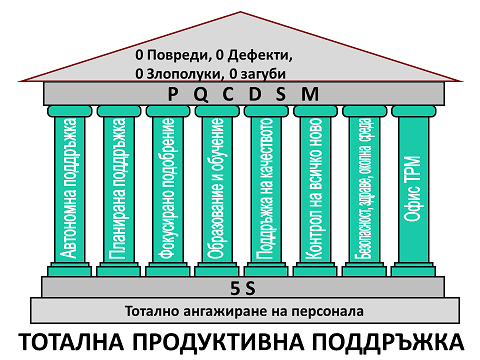

TPM - TOTAL PRODUCTIVE MAINTENANCE AND SMED - QUICK RECONFIGURATION

TOPIC TRAINING: TPM – ТОТАЛНА ПРОДУКТИВНА ПОДДРЪЖКА И SMED – БЪРЗА ПРЕНАСТРОЙКА или „Как да постигнем максимална ефективност на оборудването“ и „Как драстично да намалим времето за пренастройка?“ Защо ТРМ и SMED? Injuries in the company often surprise you? The cleanliness of the machines is not at the desired level and the operators do not take care of them?...

Kan-ban in action.

Кан-бан в действие Във фирма за производство на автомобилни компоненти, we consulted on the implementation of pulling systems, which we call Kan-ban in action. Through them, it was aimed to switch to "withdrawal" of the materials and blanks from the previous production units and from the company's warehouse. Решението за използването на Кан-бан беше продиктувано от ...

Lean production optimization

Lean production optimization and "Just in time" (Just in Time). Analysis, planning, implementation, stream optimization. Results. The project (Lean production optimization), which we will present to you aims to acquaint you with the main stages through a real example, which includes the implementation of our model - "World class manufacturing". Проектът се реализира...

Implementation of TPM in a pilot line

Внедряване на TPM в пилотна линия В голямо предприятие от металообработващата индустрия съвместно с мениджмънта работихме за внедряването на модула „Тотална продуктивна поддръжка“ (TPM). In this article we will show you some details of the work on Implementing TPM in a pilot line. Първоначално ръководството ни покани с искане да съдействаме за...

Kan-ban in action

[:bg]Kan-ban in action. In an automotive component manufacturing company, we consulted on the implementation of Kan-ban systems. Through them, it was aimed to switch to "withdrawal" of the materials and blanks from the previous production units and from the company's warehouse. The decision to use Kan-ban was dictated by several issues. Големият асортимент...