Projects

Consulting projects of Lean Bulgaria Ltd. are of great interest to the industry for several key reasons:

1. Practical solutions

- Real results: Consulting projects are aimed at achieving concrete and measurable results, which lead to increased efficiency and productivity.

- Personalized approaches: The solutions are tailored to the specific needs and challenges of each individual organization.

2. Expert experience

- Professionalism and experience: The consultants of Lean Bulgaria Ltd. have many years of experience and deep knowledge in various industrial sectors.

- Success stories: The company has many successful projects, that prove the effectiveness of their approaches and methodologies.

3. Implementation of established methodologies

- Lean production technology: Application of proven Lean methodologies such as 5S, Kaizen, SMED and others, which lead to significant improvement of production processes.

- World standards: Implementation of world-class practices, which help companies achieve high standards of quality and efficiency.

4. Improving quality and productivity

- Optimization of processes: The projects are aimed at optimization of production processes, reducing redundancies and improving quality.

- Quality management: Implementation of quality management systems, which guarantee stability and consistency of the products.

5. Human Resources Development

- Education and development: Consulting projects include training and staff development programs, which increase the qualification and motivation of employees.

- Commitment and a culture of continuous improvement: Creating a culture of continuous improvement and actively involving employees in the process.

6. Innovative solutions

- Adapting to new technologies: Implementation of innovative technologies and methods to improve production processes.

- A proactive approach to change: Assisting companies in proactively managing changes and adapting to new market conditions.

7. Competitive advantage

- Increased competitiveness: The companies, who work with Lean Bulgaria OOD, can achieve sustainable competitive advantage through process optimization and quality improvement.

- Strategic planning: Assist in the development of strategic plans for long-term success and sustainable growth.

In companies, which are large or have a more complex structure, we choose "pilot area" for implementation. It empowers us as consultants and the implementation team, to focus and implement the necessary steps in a relatively short time on a smaller scale. The pilot phase is a learning stage for the organization, as she acquires significant practical knowledge and skills of the Lean methodology. It shows management on a small scale how the company will change, how much time and what resources will be required for a complete transformation. After the work in the pilot area is completed, the project is rolled out throughout the company.

Summary:

The consulting projects of Lean Bulgaria Ltd. are of interest to the industry because of their focus on real results, expertise, the implementation of established methodologies and contribution to improving quality and productivity. These projects not only optimize production processes, but also develop human resources, foster innovation and help companies achieve sustainable competitive advantage.

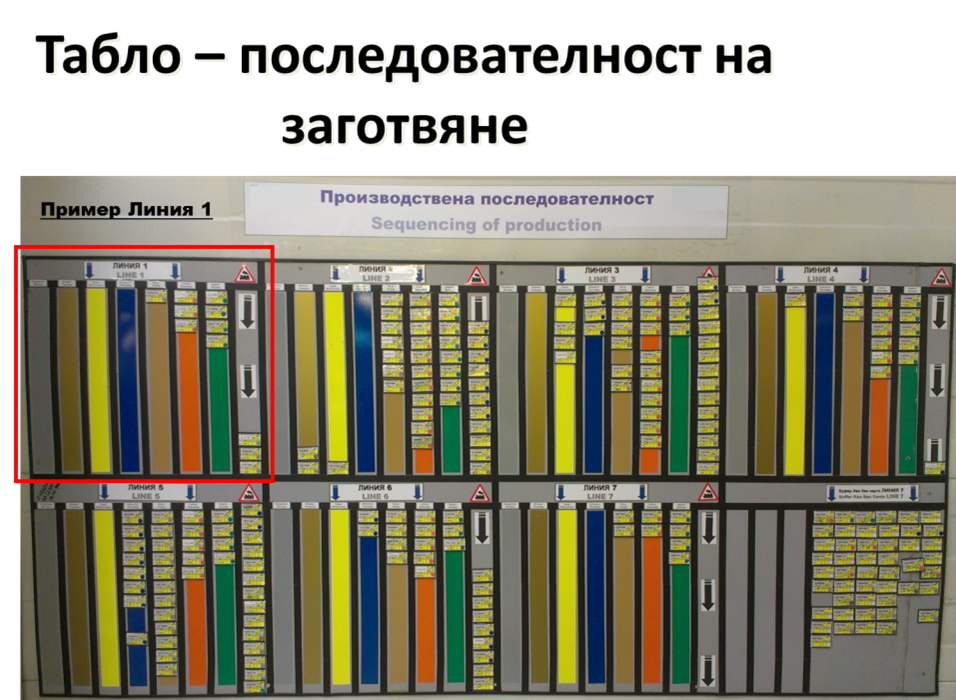

From below you can see parts of our projects and get an idea of what changes can happen through our work together: