5 S - Five steps to organizing the workplace

We all want our workplaces to be clean and tidy, so that operators don't waste time searching for adjustment keys, for technicians to find the parts and tools they need in the shortest possible time, the workshop to look neat, etc. However, everyday life confronts us with the opposite state – chaos, dirt, disorder. This depends on at least two things - on the existence of a system and on the discipline of people, or in other words there is a need for 5 S - Five steps to organizing the workplace.

the opposite state – chaos, dirt, disorder. This depends on at least two things - on the existence of a system and on the discipline of people, or in other words there is a need for 5 S - Five steps to organizing the workplace.

On the one hand, we have noticed, that at our latitudes we tend to save ourselves the "extra" effort of tidying and cleaning at work. It's kind of easier, if, after you have finished the not easy job of re-tuning the machine, you throw the key into the toolbox, even if the colleague after you has to look for it. Or skip cleaning the workplace, especially if it is a mass practice. Similar examples - many. Neglecting behavior initially gives the impression of poor discipline.

On the other hand, with a closer look at the work environment, we usually find a total or partial lack of simple and visible methods of organization, arrangement keeping clean. And then the method, which are detailed to each subject, so that it is clear how to use and return. 5 S aims for just that – the creation of a system that o easy for people to follow.

o easy for people to follow.

What is 5 S?

In short 5 S is a system, in which through various practical methods, implemented with a team effort by people, workplaces are kept tidy and clean, sections and workshops.

A good arrangement in the workshop is in itself a condition for the efficiency of the processes, as it saves operators time. On the other hand, it is also a barometer of quality: by how the workers treat the tools, which they use, how they maintain the cleanliness of their workplaces can be judged on their attitude to the work itself and to quality. In summary 5 S gives us an overall assessment of the commitment of workers and management to the firm and its condition.

5S with 5 Japanese words starting with S, which we translate as follows:

- 1. Seiri – Sort

- 2. Seiton - System arrangement

- 3. Seiso – Radiant purity

- 4. Seiketsu – Standardized

- 5. Shitsuke – Self-discipline

1S - "Sort" is a step, which requires the workplace to have only the necessary items. When we start implementing 5S, we must first sort them - necessary and unnecessary. This de facto means touching every single object in the workspace and evaluating it as necessary or not. Often in everyday life, day after day, we tend to accumulate things, who "will ever need", while it is no longer clear which are the most urgent and needed. After applying the methods in 1 S the work environment is "lightened" by unnecessary objects, it becomes clearer to detect problems and implement improvements.

2S means "System arrangement“, i.e. are included in it 2 things - system and arrangement. Very often in our work we do only the first - arrangement - of the objects, which means, that we put them in a certain order, sequence etc. But this turns out to be insufficient. After a short time we find them again in chaos. The reason for this is, that we have not created a system. The methods in 2 S help us make the arrangement like this, so that even an outsider to the workshop can find out what is left where, from where it can pass, Are there any missing items?, is there restocking etc.

After 1S and 2S, the workshop should look like a well organized airport terminal - everything well marked, visualized, that there are no unnecessary objects, etc.

The next train is 3S - "Shine Clean". It is not limited to dirt removal activities, but requires that while we clean we inspect the workplaces for problems and anomalies and correct them. I.e. 3S stands for cleaning for inspection purposes. It requires us to ask ourselves questions like: “where is the leak coming from?“, “how can I prevent dirt?“, "where we have forgotten the missing 4 the key?“, “why does this material build up?"etc. 3S helps us maintain the previous 1S and 2S. Here we can also develop schedules for cleaning and allocating areas.

4S is "Standardization". There will be no sense and completeness of a system, if it is not understood and applied in the same way by all people. The methods in 4S help us to do exactly this – to develop the previous steps in the same way for all jobs throughout the company. Let's also create rules for them and make them part of the daily work.

The fifth step in 5S is called "Self Discipline". This is the step, which is applied last and is directly dependent on the application of the previous ones one by one. For Bulgaria, this turns out to be difficult to understand - we almost always come across the opinion that "discipline should be at the beginning, because nothing else will be able to be achieved". It probably is to a large extent. But we can hardly expect from people the discipline of arranging tools, for example, if we don't have a good 2S - system arrangement beforehand (e.g. with instrument panel). And how to create a system arrangement, if we are overwhelmed with many unnecessary items and haven't sorted which ones are needed (1S)?

In summary this means, that the steps in 5S are built logically and sequentially. Correctly following the system leads to the desired goals - clean and tidy workplaces, comfortable and pleasant working environment.

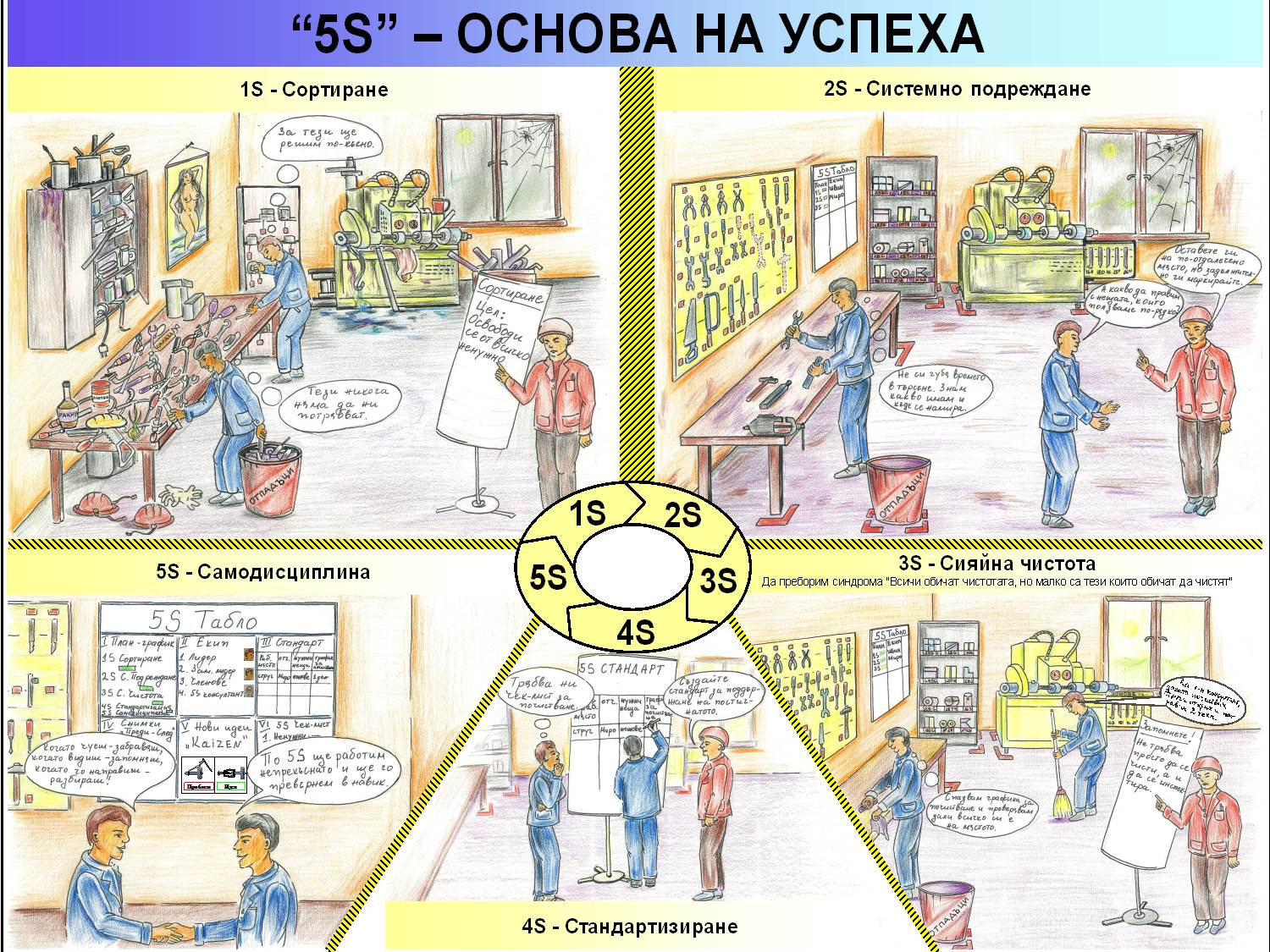

Below you can see a 5S poster developed by us, with which we present the 5 steps.