Just in time production

JIT – "Just in time" production in the Bulgarian industry sounds almost mystical. We are used to associate them with logistics activity, omitting the fact, that Just in Time is one of the two pillars of Toyota's production system.

JIT – "Just in time" production in the Bulgarian industry sounds almost mystical. We are used to associate them with logistics activity, omitting the fact, that Just in Time is one of the two pillars of Toyota's production system.

Just in time means producing just that, which is necessary, in the amount that is needed at the moment, when the customer needs it. JIT stands for: short production cycle; minimized material stocks, production and work in progress; even production load; minimal transport, high labor productivity, and on-time delivery is simply the result of all this. In summary, JIT works to reduce most of the groups of "redundancies" (established when creating the VSM).

We can only achieve these goals if we set them in this way, if we use a well-constructed methodology. In JIT, the methodology is based on several tools, and here we will mention some of them.

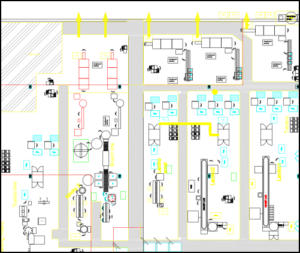

One of the main tools in JIT is the creation of an appropriate production scheme (Layout). Here, our efforts are for it to be built like this, to facilitate the production flow.

Cell production (Cellular manufacturing) is the organization of production, which relies on the grouping of production machines by product, rather than the traditional functional-guild grouping. It achieves maximum labor efficiency and minimum inventory on jobs in a given line.

Industrial leveling (Leveling) is another essential tool, which achieves distribution of product orders over time, in which there is an even load of people and machines and the need for large accumulations of materials and finished products in warehouses is avoided.

JIT tools work with the so-called. clock time (Take an hour). Here it represents time, through which the customer consumes 1 number of the given product. In companies, in which the takt time is not monitored very often leads to overproduction or vice versa - to the impossibility of fulfilling commitments made to customers.

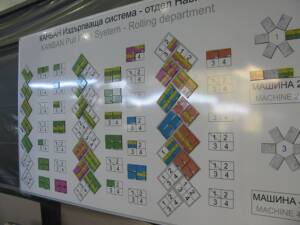

Kan-ban is a system, in which the subsequent sections "pull" the production they need from the previous sections. It uses various easy-to-understand visual signals - most often labels, markings for min/max etc. Kan-ban de facto manages cross-shops (in-house) orders without planning. It helps us to have the necessary blanks and semi-finished products available while maintaining a minimum stock of them.

Special focus in JIT – Just-in-time production is allocated to readjustment time. Often, when it is longer we tend to produce larger batches to reduce downtime per unit of production. However, this leads to the accumulation of large quantities of work in progress. The SMEM tool helps us with this problem - "Change matrix in one minute" (BLACKSMITH). Here, the focus is on a perceived problem—namely, how to improve the readjustment procedure itself, so that it does not take much time.

Built together, these tools help us achieve harmony in the operation of all units and a smooth production flow, delivering the right products just in time.