below you can see an English translation

Lean project in the food industry

In several places we came across comments, that lean tools are not applied in the food industry (HVP). The purpose of the article is to refute these claims and to briefly share the effects, which can be achieved there.

In a medium-sized company from HVP, producing dessert bars, we started a project to improve the organization, through lean tools. The company is relatively young – at approx 5 years, produces an innovative product and grows rapidly.

Until now, not much attention has been paid to the efficiency of production. Apparently the lines creating added value were not balanced well, from which momentary accumulations of work-in-progress were obtained, partial load on operators, delay and shortage of some materials, leading to downtime of the line and people on the shop floor.

The project included:

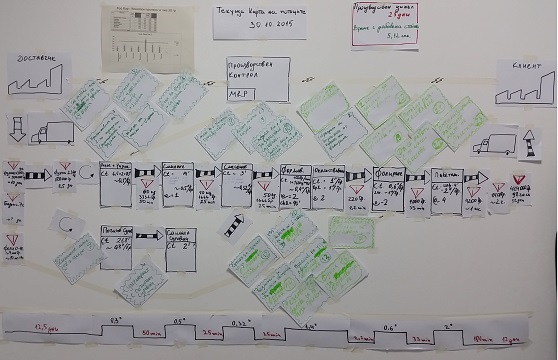

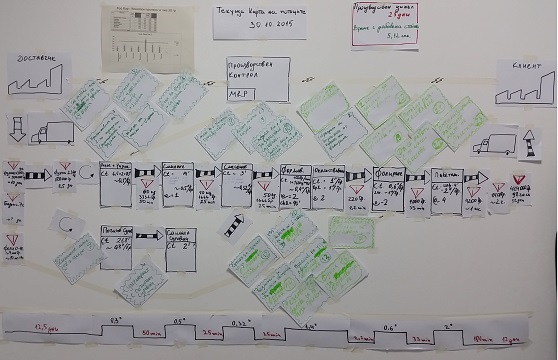

- analysis of flows and times of operations;

- improving the production floor plan;

- operator load balancing;

- creating pull systems (kan-ban) for basic materials and blanks;

- 5S by individual jobs.

It is typical here, that these tools were synchronized with the sanitary requirements typical of the industry.

According to the production manager, the main effects of the application of lean tools in the enterprise are the following:

- “We achieved very good product flow – we eliminated the unnecessary distribution of materials around the premises.

- In the model line, we have improved labor productivity by approx 20%. In the packaging business, the improvement is within the same limits.

- Introducing Kan-ban to the prepared materials helped us a lotto provide raw materials at any time without overstocking and without violating sanitary requirements. Already

Can-ban for prepared materials in the food industry no need to stop production to make blanks, and on the other hand we do not keep a large stock of them.

- Work in tact. We convinced ourselves, that it is possible to achieve better labor productivity in synchronized work, even at lower machine speed.

- We sorted and organized the warehouses.

- We specified the amount of raw materials and materials in stock. It used to happen that we would run out of basic materials and stop work, as the delivery time is 3 the month. Now with lean tools we have determined the times when to order materials for the warehouse, so we don't overstock there either.

- 5S helped us to be more tidy and organized.”

Here's hoping, to have convinced colleagues from the HVP, that it, as opportunities for improvement and application of lean tools, is not much different from the others, including. the automotive industry.

[:in]

Lean project in food industry

At several occasions we’ve come across comments that the Lean tools are not being applied in the food industry in Bulgaria. The aim of the post is to disprove these statements and to share in short the effects that can be achieved there.

In an average size company producing sweet blocks we started a project for improving the organization through the Lean tools. The company is relatively young – at about 5 years old, it produces an innovative product and is growing fast.

Till now big attention was not given to the effectiveness of the production. Visibly the Value-adding lines were not well balanced, and many different wastes were happening: piles of Inventory (work in progress) at certain moments, uneven and incomplete operators’ loading, delaying and shortage of some materials leading to downtime of machines and people in the shopfloor.

The Lean Project included:

- Analysis of the flow and timing of the operations;

- Improvement of the layout of the production;

- Balancing of the load of the operators;

- Creation of pull systems (Kan-ban) for the main materials and sub-products;

- 5S introduction at workstations.

Distinctively for the project – these tools were synchronized with the sanitary requirements typical for that industry.

By the words of the production manager the main effects of the application of the Lean tools are the following:

- “We achieved very good flow of the products – we eliminated unnecessary handling and transport of materials in the shopfloor.

- In the pilot line the labor productivity was increased at about 20%. In the packing activities the improvement was with the same scope.

- The introduction of Kan-ban for the materials and sub-products helped us a lot to have available all needed materials at any time without overstocking and violation of the hygiene requirements. Already there is no need to stop the production to prepare sub-products and from the other side we do not keep big inventory of them.

- Working in a takt. We are convinced now that it is possible to achieve better labor productivity if the work is synchronized, even if the pace of some machines is reduced.

- We arranged and organized the warehouses.

- We optimized the quantities of materials in the stores. Before it was happening that we were left without main materials and had to stop work as the lead time of some materials is 3 months. By using the lean tools we defined the reorder points for the materials in a way to prevent overstocking also.

- 5S helped us to be more orderly and organized.”

With all this we hope that we have convinced the colleagues regarding possibilities for improvement and Lean application the food industry is not much different from the other industries including the automotive.

[:]