Implementation of TPM in a pilot line

In a large enterprise from the metalworking industry, together with the management, we worked on the implementation of the "Total Productive Support" module (TPM). In this article we will show you some details of the work on Implementing TPM in a pilot line.

Management initially invited us with a request to assist in "optimizing maintenance activity to improve results". At our first meeting we were introduced to a number of issues. Half of the equipment was old, in general, production lines were large and heavy to maintain. Emergency shutdowns were a daily occurrence for production, and followed a number of other losses. The reasons for the problems, according to management, were related to the lack of knowledge and motivation among people and the lack of clearly established rules and procedures. As a result, of course, it turned out to be, that the lack of knowledge is not among the real problems of the company.

The initial analysis

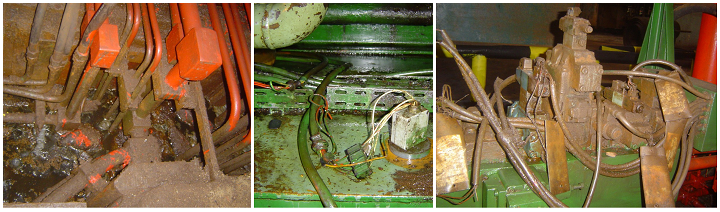

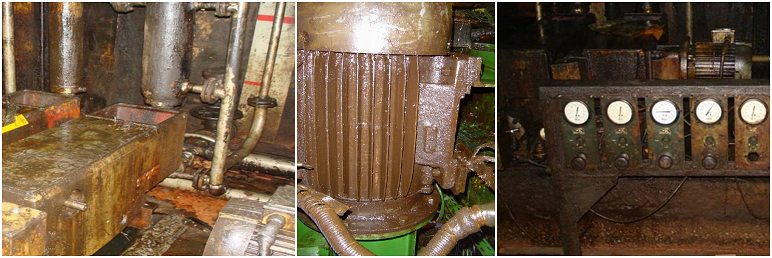

In the initial analysis, we focused on one of the main lines. There, the main reasons for the problems with the machines were revealed. In the first place, the so-called "basic condition" of the machines was neglected. System cleaning has never been maintained, in parallel with which the daily inspection also deteriorated. Even with the naked eye, a large number of fugai were visible (minor anomalies) such as missing fasteners, slacks, poorly routed cables, etc.

Automatic greasing units were destroyed over time, a clear and universally understood manual greasing system was not built. It was done on some of the points, and even their number was not known to all the mechanics. Most of them (over 60 %) they were covered with dust and dirt and only reminded of themselves when the corresponding node was worn or damaged.

The underground fluid lubrication and hydraulic systems were also caked in dust and dirt. They had a large number of small leaks, which further worsened the picture. There was no visualization of control devices along the line, fluid flows, cables, etc.. Only the most experienced workers actually knew the entire system.

The indicator of overall efficiency of the equipment (ABOUT HER) on the line was low – approx 40 %, with the main reason for this being the low order load and working at a lower speed. However, he showed us the effect of the machines' "ground state" - 12 % since then it was down due to accidents (around 8 %) and planned repairs. But due to the presence of downtime from lack of orders, MTBF indicators were preferred as the starting point of the analysis (mean time between failures) и MTTR (average time to repair). MTBF also showed low results – approx 9 o'clock (all work interruptions due to breakdowns were included in the data, regardless of their duration and severity).

This generally resulted in a low degree of line reliability. Operators preferred to "slow down" to "protect" the machines. From there, the productivity of the line and of labor was understated. Accidents led to other bigger losses - defects, deals on spare parts, order delays.

The line was chosen as a "pilot" for the implementation of TRM for several reasons. First of all, it was technologically the only one to perform a certain operation and was a bottleneck in the flow of certain types of production. Secondly, it was of the old lines and accordingly had a burning number of accumulated anomalies and problems.

Deployment approach

The implementation focused on the first pillars of TRM - Autonomous Maintenance, Planned Maintenance and Focused Improvement.

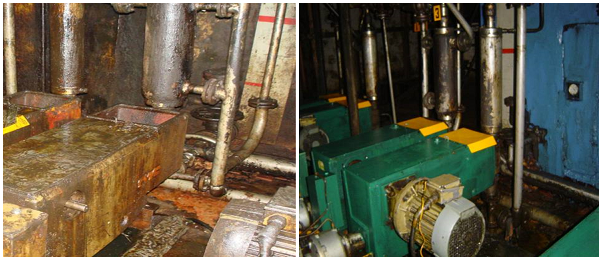

It started with the first step of AP - "Initial cleaning". They were identified 245 and removed 217 Fugai (minor anomalies) including all leaks. The line achieved zero oil loss.

The ideas of operators and technicians were realized 13 kaizens (improvements) to facilitate access for cleaning and inspection of hard-to-reach parts. In some places, ideas to reduce pollution and control dirt at critical nodes were also implemented.

A complete visualization of the line's systems was created in a standardized way. Thus, the unit acquired a good vision and clarity of operation. A comprehensive cleaning system was created, lubrication and daily inspection with responsible unit operators.

In the Planned Maintenance pillar, the R&D plans were updated, a "visual" warehouse of consumables and spare parts was created, which must always be available.

Results:

As a result, OEE grew to 49 % (downtime due to lack of orders is also taken into account in the OEE calculation). Dwell time reduced to 5 %, most of which was for planned repairs. MTBF rose to 22 o'clock.

The company's team accepted the achieved results as a starting point for further improvements to the unit. More are planned 11 kaizens to facilitate maintenance, as well as the removal of the others 38 anomalies.

Overall, the results encouraged management to plan for the deployment of TRM throughout the enterprise as well.