The example, which will be considered refers to production, which sews headrest covers for cars. The volumes, with which to work are large – around 20 thousands a day of 500 operator. Before the introduction of pull system, the chaos in the production lines created many problems such as:

- accumulation of a huge amount of materials in the production lines

- falling behind the production plan and not being able to follow FIFO

- uncertainty about the implementation of the set plan

- wasting time in search of necessary materials for production

- lack of space

- overloading of logisticians and preparers

The work was organized as follows. The planner makes weekly planning based on the customer orders entered in the system. The plan is printed and distributed to the 7 chief lines, of shift supervisor, of the preparers – the people, which complete the patterns needed to sew the cases and the logistics – the people, which deliver the prepared materials from the billet shop to production. Everyone has the same plan and strives to follow it without caring if the next one after him is ready i.e. is. cooks cook, these products, which are easier and faster to cook, and logistics brings everything into production, which is prepared without caring if the operators have sewn the previous one and if they even need it. All this is a prerequisite for the chaos described a moment ago. The described situation fully corresponds to t. Sun. PUSH system.

The PULL system is a solution, which will make the work as easy as possible. Now, with the help of pictures, we will present to you how the system works.

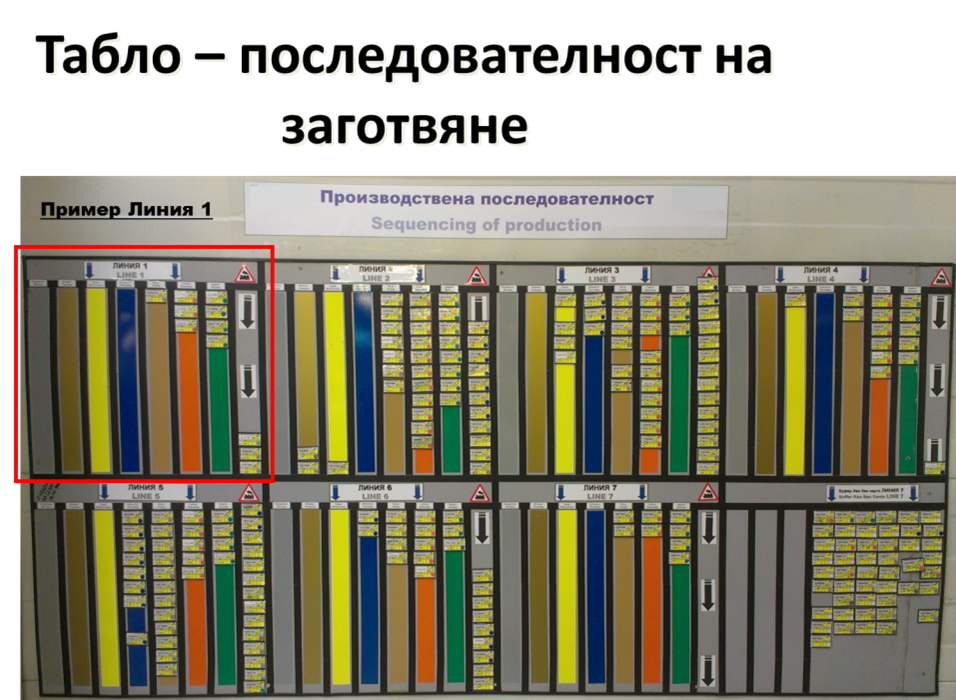

A metal panel was created, on which the production plan for each line is visualized with magnetic Kanban cards. The board is placed in the workshop for preparing patterns.

We will look at the situation in Line 1.

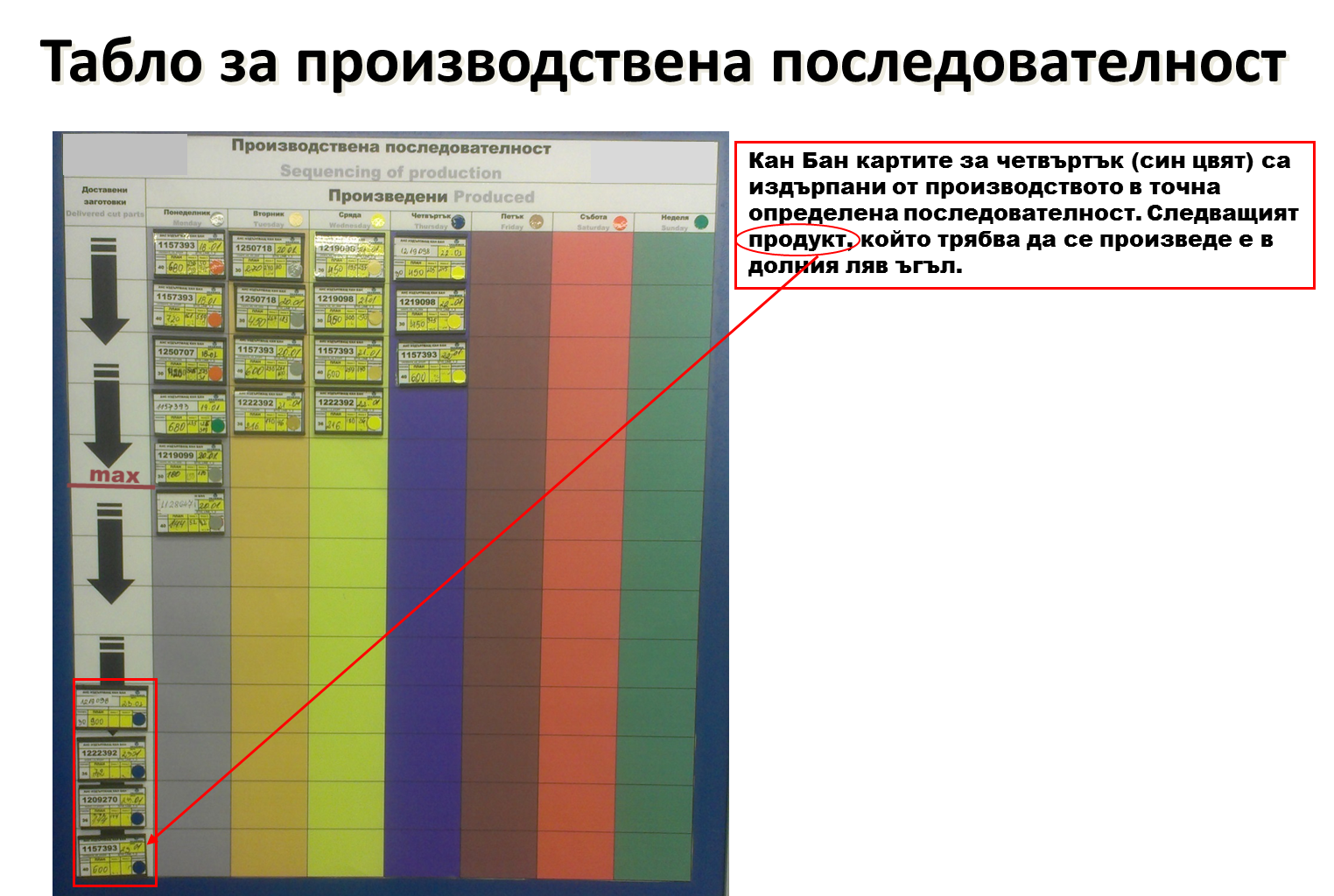

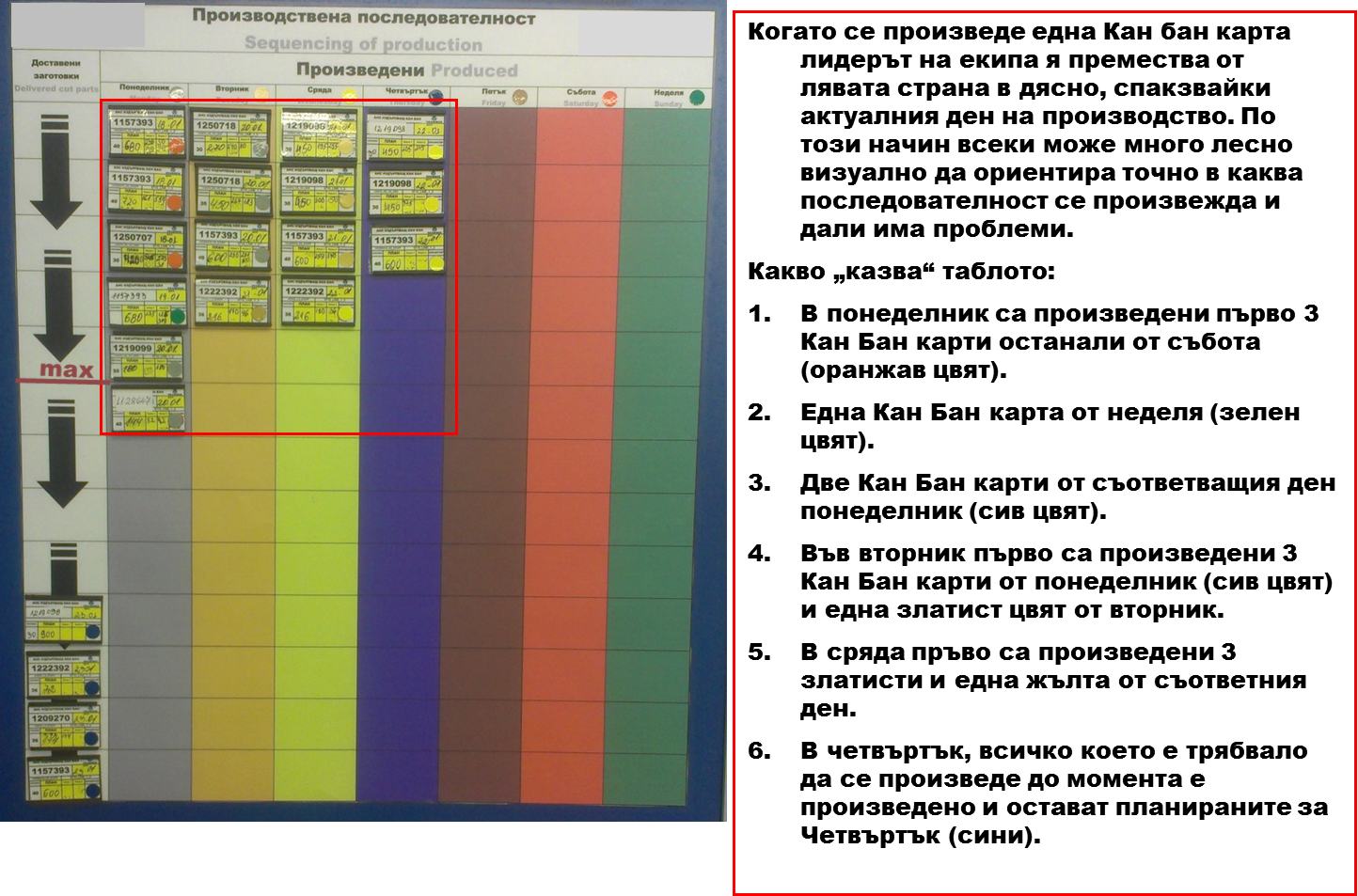

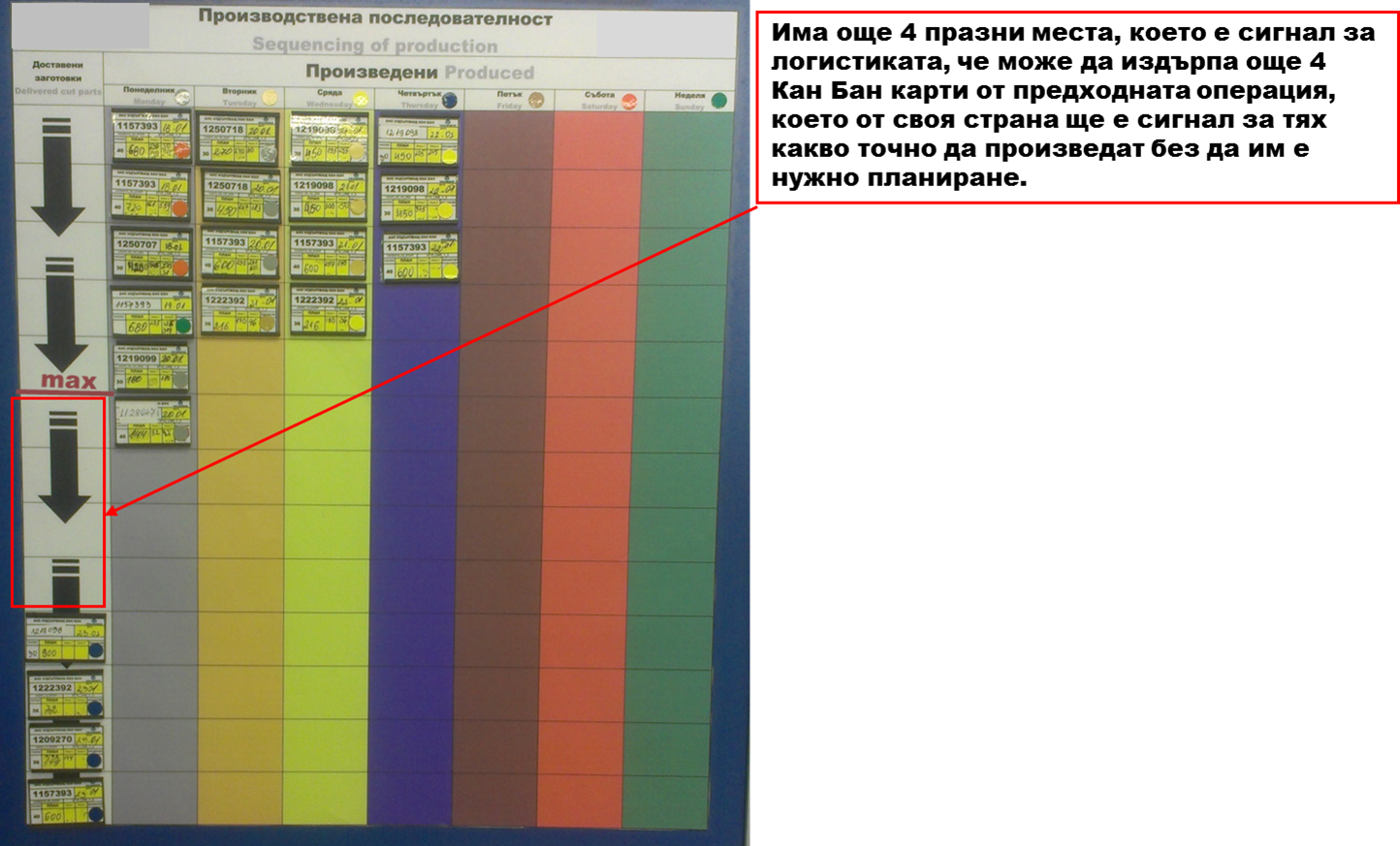

So far we have looked at part of the dashboard, which is located in the preparation room, and we will see how it communicates with the board in the line. There is a separate board for each line, which is called “Production sequence dashboard”. Again, we continue to monitor what is happening in Line 1.

The results, which were achieved:

- The weekly paper plan no longer exists, no time is wasted in reading, checking back and checking how far we've come, what needs to be prepared and what needs to be produced.

- Visual management - managers can easily navigate what is happening in the production areas.

- The pulling system does not allow blanks to accumulate in the production lines, which are not yet needed and are a prerequisite for house and waste of time in search.

- The team leader easily follows the production sequence.

- Operators no longer choose the easiest products , and follow a sequence determined by the end customer.

- Customer satisfaction improves.

As you can see when creating pull systems you have to be very inventive. There are no generally valid solutions, so the main thing is to follow the principle of pull and work in a team.