Transformation in an engineering enterprise through 5S. The implementation of 5S is implemented as a project, which facilitates change in our customers. In mechanical engineering, where different machines and individual jobs create a challenging environment, The accumulation of unnecessary items and dirt often leads to chaos. Without a well-established 5S system or practices,...

Basics of Lean methodology with production simulation

Основи на Лийн методологията с производствена симулация или „Как да изградим производство „Точно навреме“, applying lean principles?“ Защо Лийн принципи и Производство „точно навреме“? The fulfillment of your orders is often delayed? You are overwhelmed with different types of blanks and materials, and others often fall short? You have a large volume of work in progress on the lines? Poor communication between planning,...

Training calendar

Календар за предстоящи обучения Ако изпълнението на поръчките закъснява. If labor productivity is low due to excess movements, cross streams etc. If you have a large volume of work in progress, involving a lot of funds. Ако искате да се справите с хаоса и мръсотията по работните места Ако има недобра комуникация между...

TPM – Total Productive Support

TPM - Тотална Продуктивна Поддръжка или „Как да постигнем максимална ефективност на оборудването?“ Защо TPM - Total Productive Support? Injuries in the company often surprise you? The cleanliness of the machines is not at the desired level? You have high costs for spare parts and losses from downtime and process disruption? Постоянно чувате оправдания...

Certified Lean Practitioner

Сертифициран Lean Практик Тридневен курс на български език с онлайн изпит и сертификат от ILSSI. The internationally certified and accredited course for "Certified Lean Practitioner" teaches managers and employees how to use methods, Lean tools and techniques to improve their business processes. Участниците ще разберат как да водят малки...

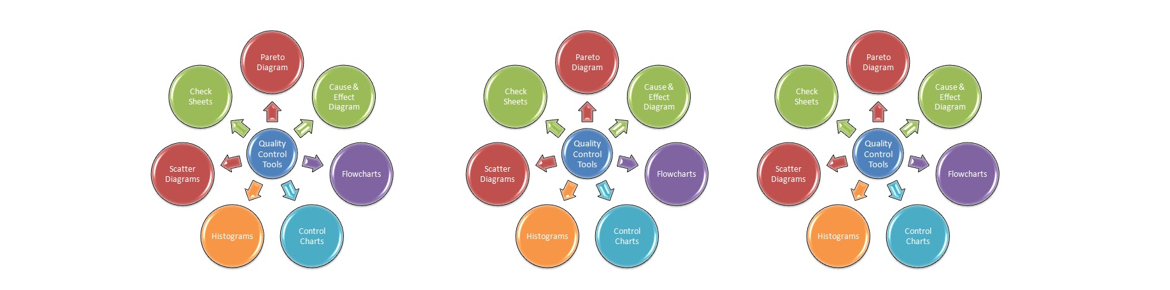

7 QC tools – 7 basic quality tools

7 QC tools - 7 основни инструменти за качество Обучението по 7 basic quality tools (7 QC tools) is important for everyone, who wants to improve processes and quality in their organization. Here are some of the main reasons why you should enroll in this training: Подобряване на качеството на...

ТPM – Total productive support

TPM - Total productive support (Total Productive maintenance) ТPM - Total productive maintenance is a system, created and developed in Japan over several decades. With an initial focus on manufacturing and machinery, it evolved into a program, covering almost all activities in the organization. TRM is aimed at: създаване на фирмена култура...

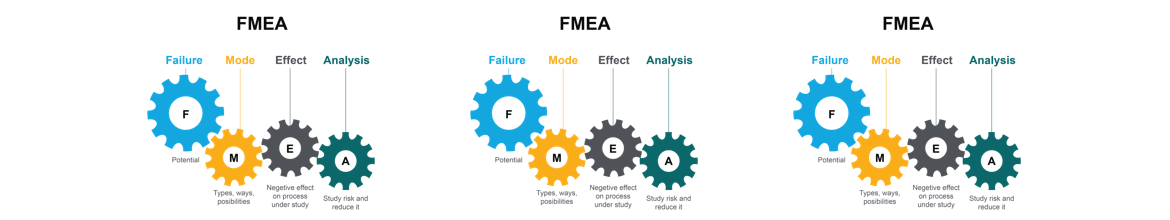

FMEA – Failure Modes Analysis and Their Effects

FMEA – Анализ на режимите на отказ и ефекта от тях Обучението по FMEA (Failure Mode and Effects Analysis) or Analysis of failure modes and their effect is essential for organizations, who want to improve their ability to identify and manage risks, свързани с продуктите...

Lean Six Sigma – Green belt

Lean Six Sigma training and certification - Зелен колан Петдневен курс на български език с онлайн изпит и сертификат от ILSSI. The internationally certified and accredited course for "Green belt" Lean Six Sigma teaches managers and workers how to use methods, инструменти и техники на Lean Six Sigma за...

Day-to-day management and problem solving

DAILY PRODUCTION MANAGEMENT (SHOPFLOOR MANAGEMENT – SFM) AND TROUBLESHOOTING TOOLS (PROBLEM SOLVING TOOLS -PST) or “ How to find and deal with the root causes of problems? How to improve results on a daily basis?“ С какво са важни тези инструменти? Проблемите ни изненадват и нямаме подход...