IN ORDER, CLEAN AND EFFICIENT PRODUCTION

Lean Bulgaria LTD

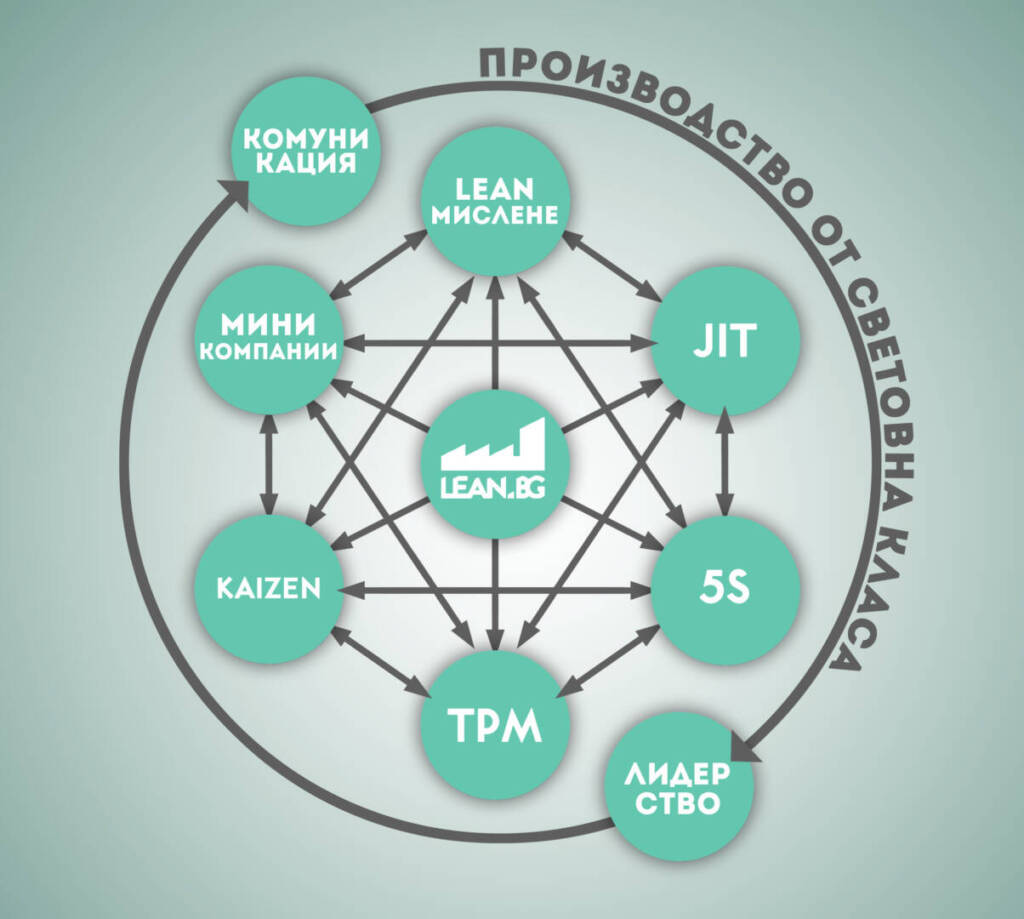

Lean Bulgaria Ltd. is a consulting company with a focus on improving the efficiency of manufacturing enterprises. Our team has extensive experience in implementing the so-called. "LEAN Manufacturing" - tight production. It is a systematic set of tools, developed over several decades by leading global companies in order to achieve perfection in terms of efficiency, quality, organization. In Lean Bulgaria, we adapted these tools for the needs of Bulgarian companies and developed them as modules in the project "PSK – World Class Manufacturing'. Through it, we aim to assist management on the way to knowing and applying Lean tools to build a better production.

Lean Bulgaria LTD

WE ADD VALUE THROUGH CONTINUOUS IMPROVEMENT OF PRODUCTION EFFICIENCY

01

Mission

We help to improve the production efficiency of our customers.

02

Vision

To be the preferred partner of the Bulgarian industry in the application of Lean tools

03

Aims

to assist management on the way to knowing and applying Lean tools to build a better production.

Services

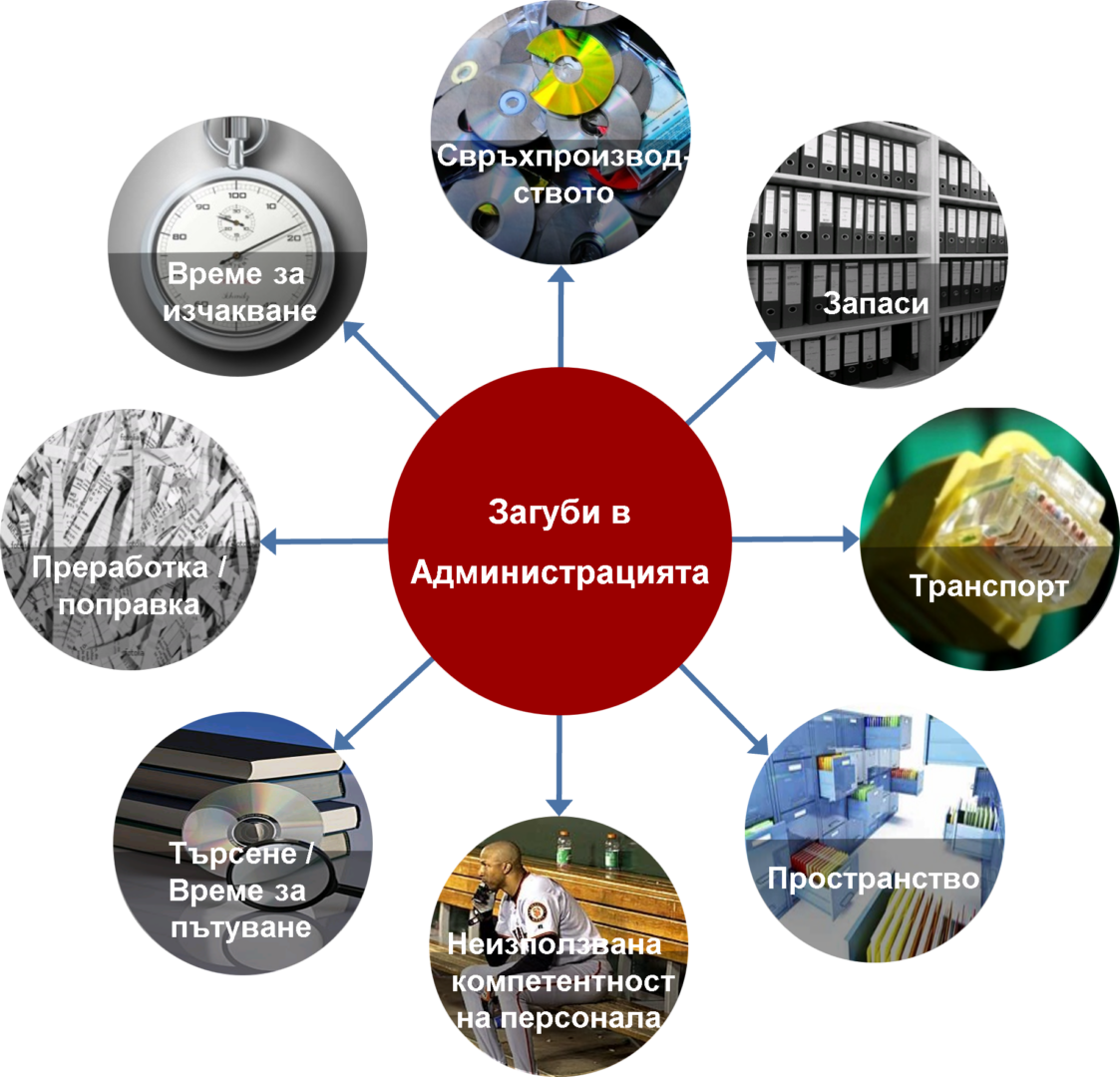

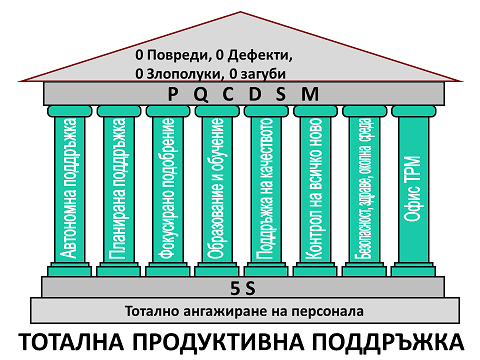

Lean Bulgaria LTD offers services to improve the production activity. Our know-how is related to the product developed for the Bulgarian market "World Class Manufacturing". The main effects after its application are: production optimization, increasing labor efficiency, improving tidiness and cleanliness, achieving peak equipment condition, improving team interaction and communication in the company.

- Public trainings

- Company trainings

- Company consulting for Lean transformation

- International certification to ILSSI (International Lean Six Sigma Institute)

World Class Manufacturing

World Class Production is a product created by the Lean Bulgaria team, whose main goal is to improve the efficiency of production enterprises. The basic principles around, which our product is built from the so-called. "LEANWCM for the sait Manufacturing" - tight production, which is a system toolkit, in order to achieve perfection in terms of efficiency, quality and organization. We have adapted these tools for the needs of Bulgarian companies and developed them as modules in "PSK - World Class Manufacturing".

“The fear, which you experience, when you are moving at the edge of your possibilities, expands your limits.

"The most important ingredient in the formula for success is being able to get along with people."